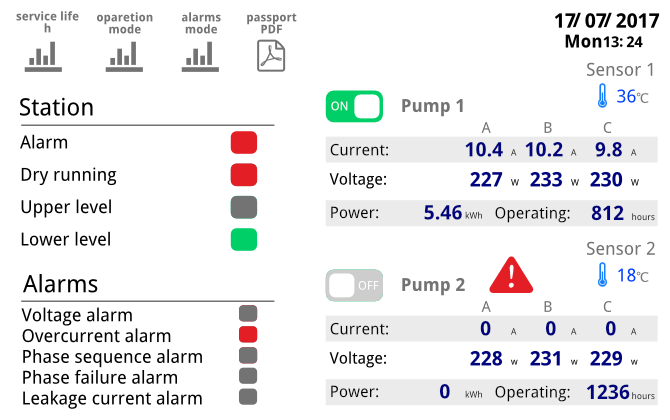

The Overvis Pump automation board was designed for the protection and control of pumping equipment.

An integrated monitoring system provides remote control of electrical network parameters and allows users to manage the system via mobile devices.

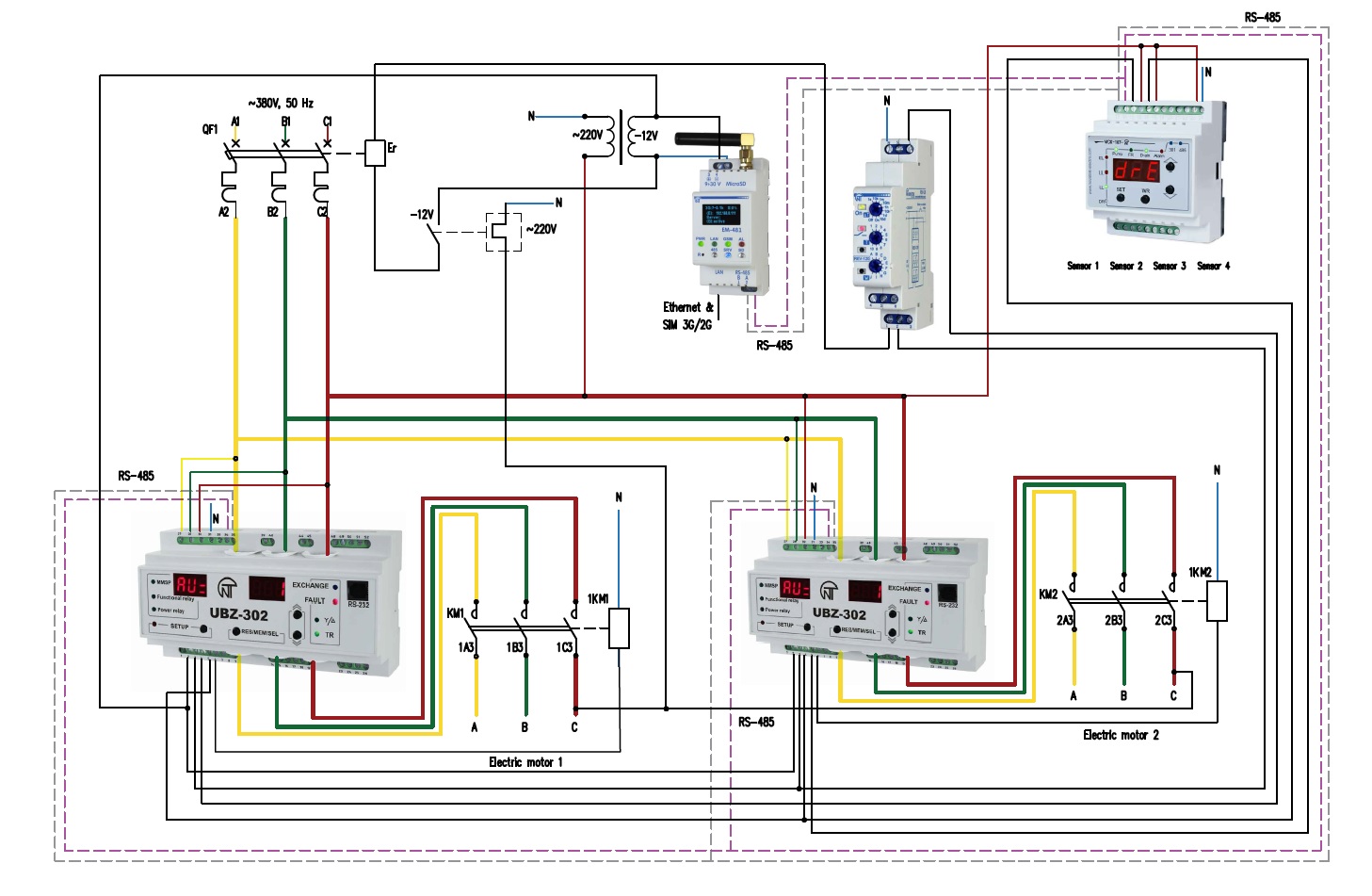

Easy way to build a unified control system over water supply units.

How to set up the control automation board:

Depending on the number of pumps and their capacity, there are appropriate automation boards with various modifications.