Overvis Ice automation board was developed for refrigerating and freezing equipment monitoring. The solution includes automatic data collection, emergency situation notifications, analytical reports on compressor operation and temperature mode control at the facility.

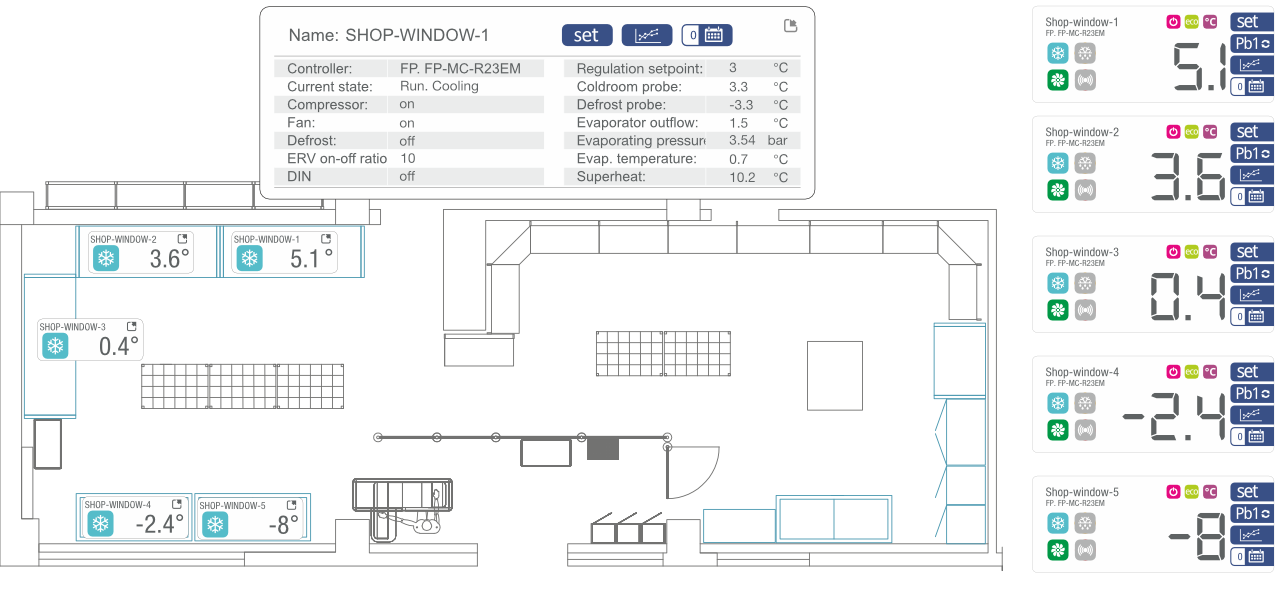

The integrated monitoring system provides remote control of refrigerating equipment status, collection of readings on energy consumption and manages units via mobile devices.

Easy way to control and manage refrigerating equipment.

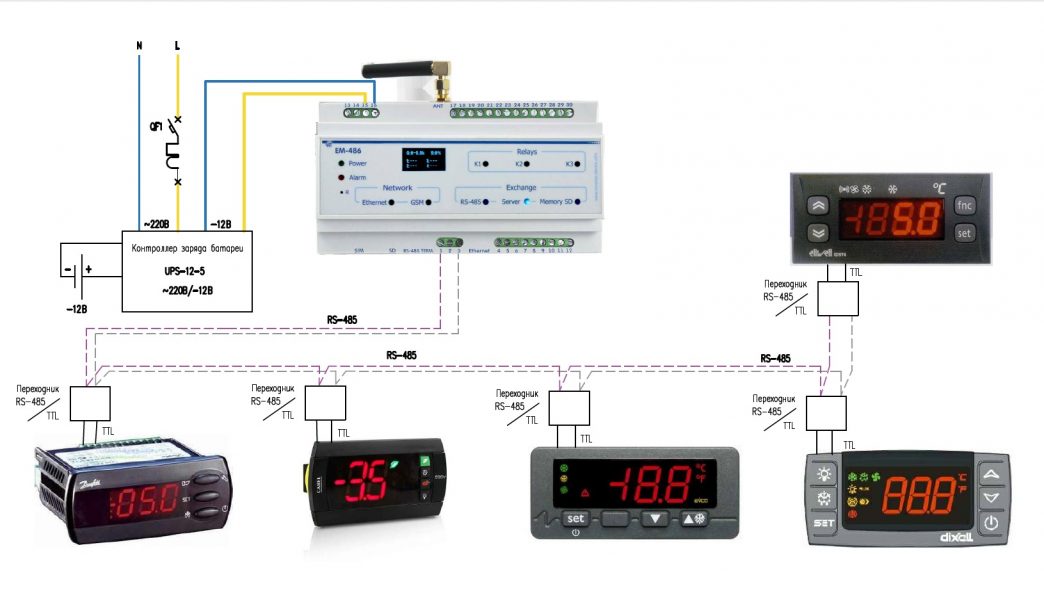

How to set up the control automation board: