Overvis Agro automation board was developed for the monitoring of electric power lines for greenhouses, as well as load control and reporting of electricity costs.

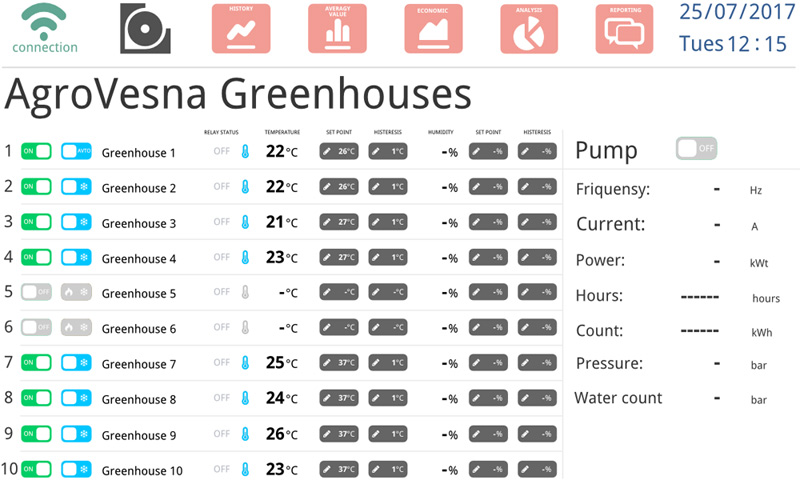

Integrated monitoring system provides remote control of electrical network parameters and load control using mobile devices.

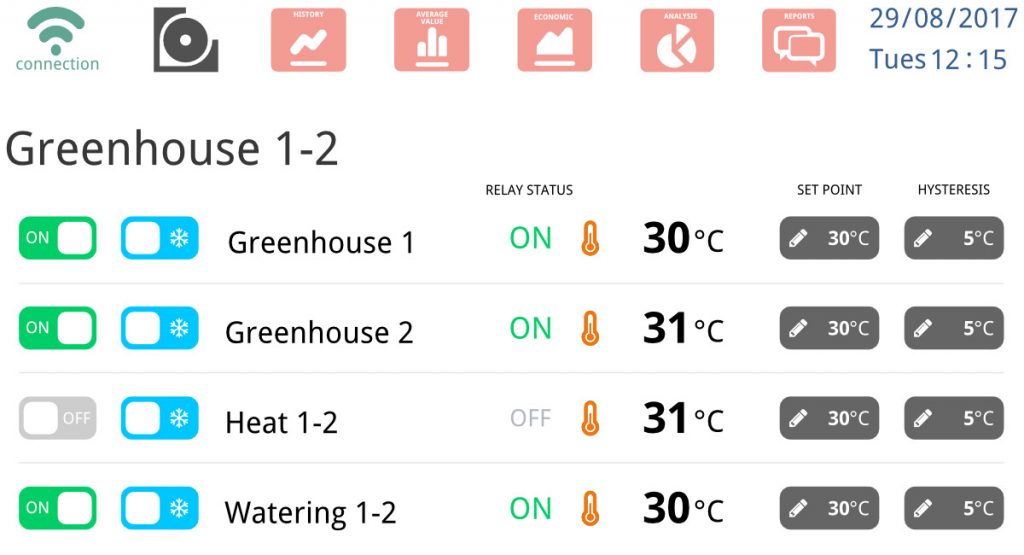

Easy way to control and manage a greenhouse’s temperature and irrigation process.

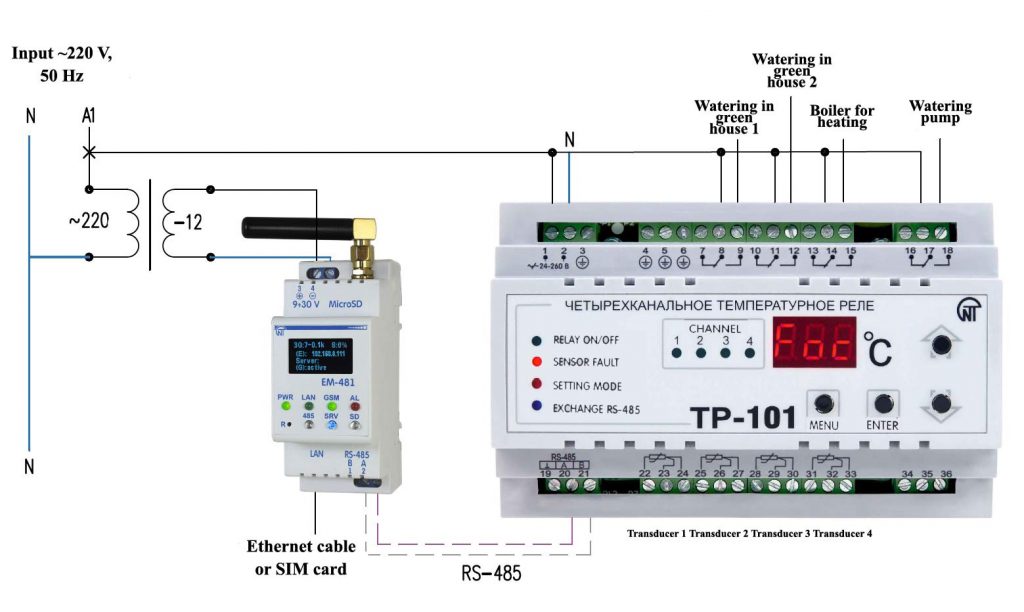

How to set up the control automation board: